Automatic solder paste printer machine for 1200mm PCB

Description:

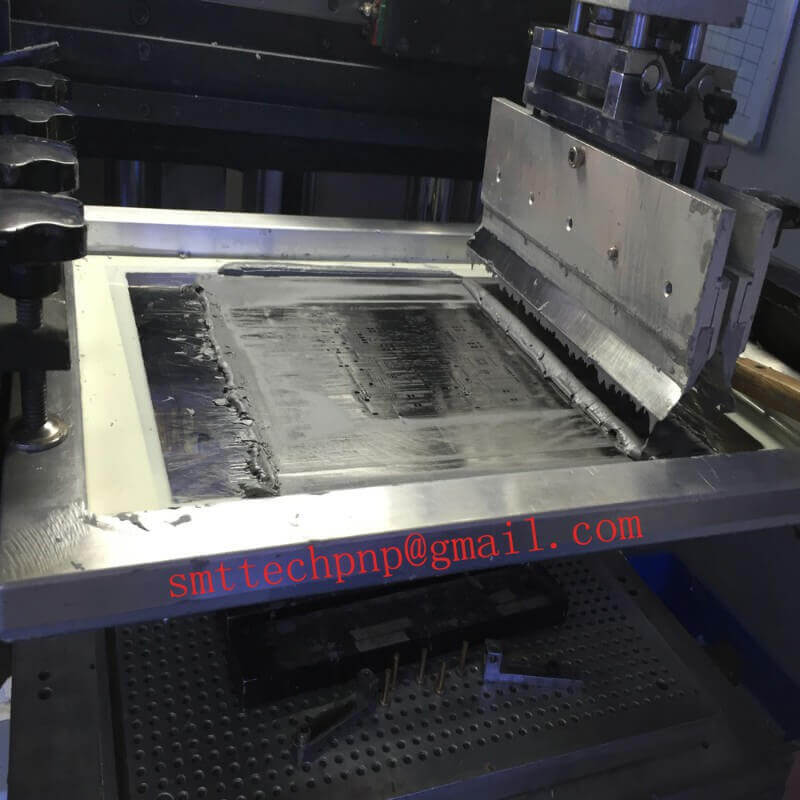

LK-F1200 Ideal for LED production which for Accuracy it has built-in ±10 micron alignment,and ±25 micron wet print repeatability (≧2.0Cpk@6sigma) with 20 seconds total throughput,including print and stencil cleaning cycles. It provides fast, quality printing for LED battens and other applicationsIt can perfectly meet the requirements of fine pitch such as 0201, 0.25pich. Fully automatic production transports the board from the loader, automatically aligns the PCB to the stencil, lowers the stenciland prints solder paste onto the pads at aprogrammable speed and pressure. The stencil then lifts up from the board—also at a programmable speed—and the board is transported upline to the next processing step. LK-F1200's unique clamping device prevents flexible boards from bending. The vacuum table holding fixture ensures that PCB lay flat. The table moves to align the PCB to the stencil.

Standard Configuration | Specification |

Total System Alignment | ± 10 microns (at 6Sigma), Cpk≧ 2 |

Wet print capability(Cpk) | ± 25 microns (at 6Sigma),Cpk≧ 2 |

Core Cycle Time | 12 secs+process |

Maximum Print Area | 1200mm*(X)×350mm(Y) |

Printer Construction | One piece optimised welded frame |

ISCAN Machine Control | integrated circuit (IC) |

Operating System | Windows XP Standard embedded |

Operator interface | Interface in English with HC Automation Copyright |

Camera | CCD Camera for Remote coaxial vision system four way independent coaxial/Annular LED light source. |

Camera Positioning | Automatic capture |

Squeegee Pressure Mechanism | Software controlled,motorised |

Stencil Positioning | Semi-Auto-Load incorporating squeegee drip tray |

Stencil Alignment | Motorised via actuators X,Y, and Theta |

Under Stencil Cleaning | Interchangeable Under Stencil leaner , fully programmable with wet/dry/vacuum wipe and the system can be programmed combination of dry wipe, wipe with solvent (“wet wiping”)(300、400、500、600mm) |

Vacuum Assist Under Stencil Cleaning | Programmable powerful vacuum suction |

Squeegee | Clamped double trailing edge squeegee (1set included) |

Machine Interface | Upline and downline SMEMA included |

Connctivity | Standard networking and USB interface available |

Tri Colour Beacon | Programmable with audible alarm |

Documentation | Operator 、installation 、electrical Drawings ,On board technical manuals |

Transport System | Specification |

Type | Single piece with 3mm “U”type transport belts ,front rail fixed |

ESD Compatibility | Transport belts and guides with surface resistivity between 10⁶ and 10ⁱⁱ ohms |

Width Adjustment | Programmable motorized rear rail |

Transport Direction | Left to right ,Right to left,Left to left, Right to right |

Board Handing Size(minimum) | 80mm(X)x50mm(Y) |

Board Handing Size(maximum) | 1200mm(X)x350mm(Y) |

Board Thickness | 0.2mm to 6mm |

Board Weight(maximum) | 3kg |

Board Warpage | <1%(Based on diagonal length) |

Board Fixture | At the bottom of the support, elastic side clamping, vacuum suction(option) |

Board Handling Features | Soft rail lift/land Board clamp regulator |

Board Underside Clearance | Programmable 13mm (25mm option) |

Process Parameter | Specification |

Print Pressure | 0~30kg programmable |

Print Speed | 10~200mm/sec |

Print Gap | 0mm to 6mm |

Substrate Separation

| Speed:0.1~25mm/sec Programmable with three step control |

Print Modes | Print/Print Print/Flood Flood/Print Adhesive |

Paste Knead | Programmable number period on demand |

Vision | Specification |

Vision System | beijing daheng |

Fiducial Recognition | Image matching, mathematical algorithm |

Fiducials | 2 or 4 |

Fiducial Types | Standard geometry, reference point, pad / hole |

Fiducial Size | 0.1mm to 3mm |

Fiducial Locations | Anywhere on substrate |

Fiducial Error Reovery | Optical automatic adjustment , automatic search reference point |

Camera Lighting | Program control LED brightness adjustment |

Standard C Chase | Specification |

Screen Frame Size (maximum) | 1500mm X 750 mm |

Screen Frame Thickness | 20mm~40mm |

Image Position | Front ,Centre , Custom |

Operating Environment | Specification |

Temperature | -20℃~+ 45℃ |

Humidity | 30%~60% relative humidity (non-condensing) |

Services | Specification |

Voltage | AC:220 Volts AC± 10% Single phase@50/60HZ 1Ф 1.5Kw |

Machine Dimensions | 2220(L)*1220(W)*1500(H)mm (excluding the height of indicating lighthouse) |

Weight | Approx:1500Kg |

Products performance:

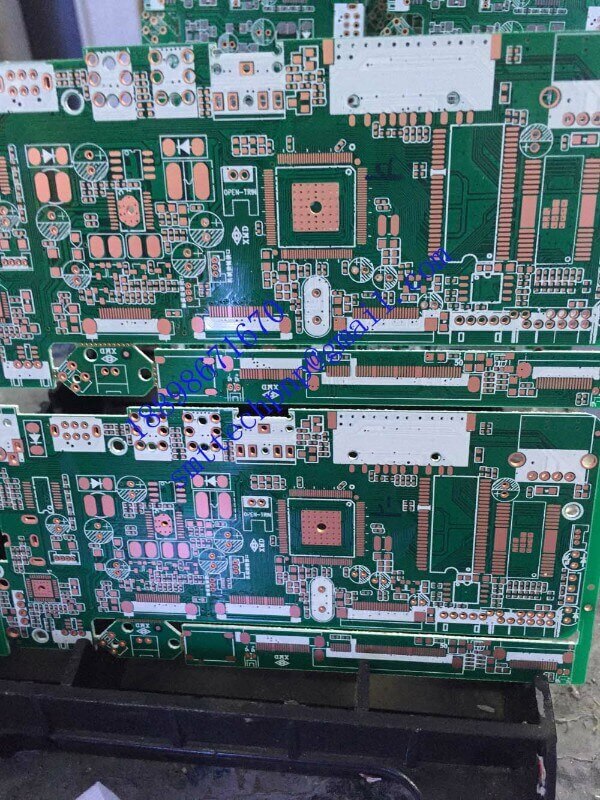

Before stencil printer

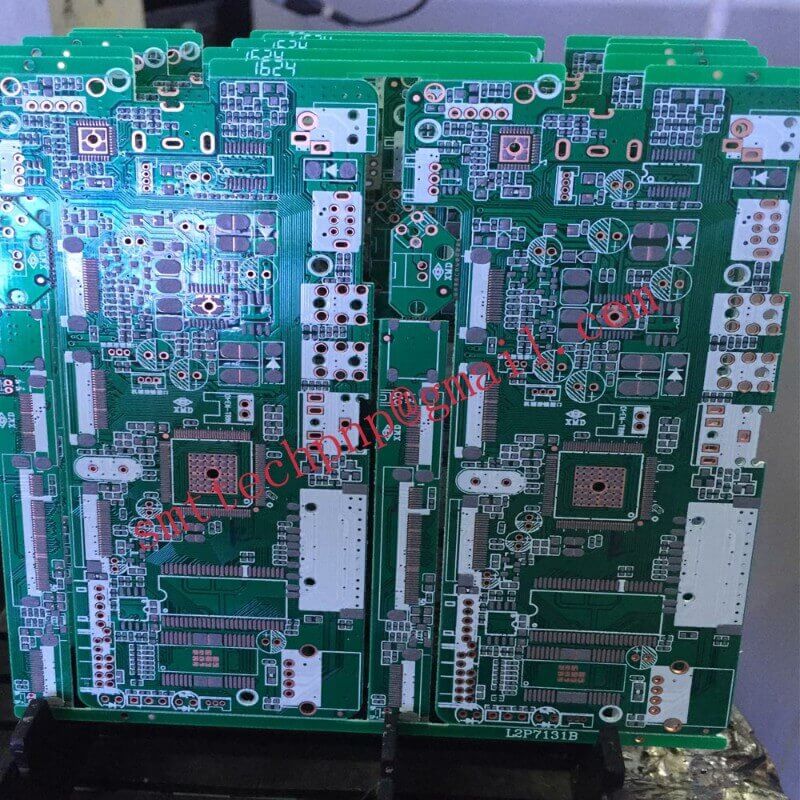

After stencil printer

For machine detailed:

If you are interested in our products, please feel freely to contact us.

Awaiting for your consulation.

Elaine Fang

skype:elaine19920114

QQ:2277025763

smttechpnp@gmail.com