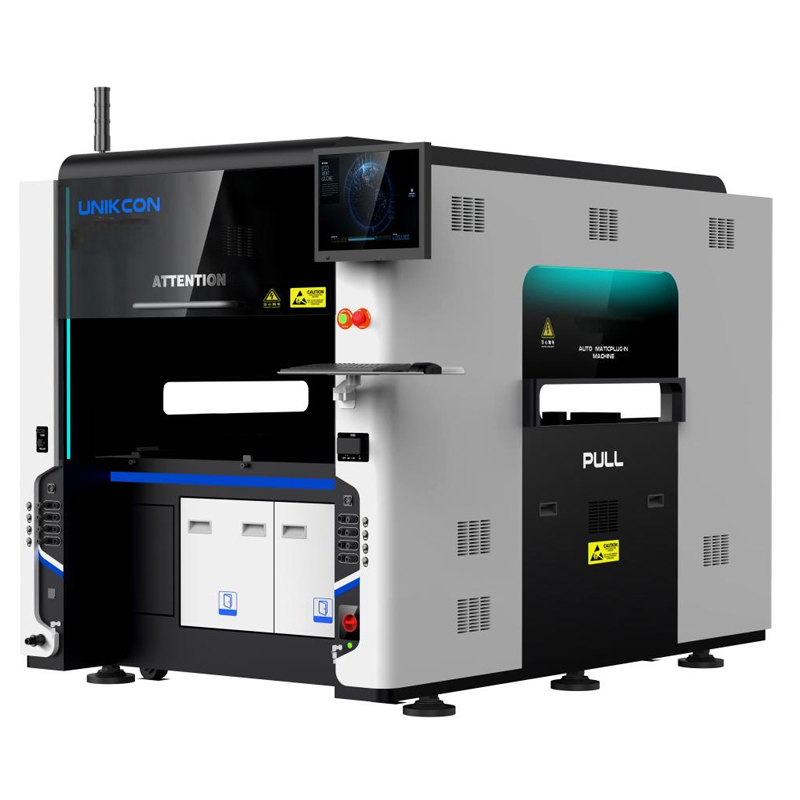

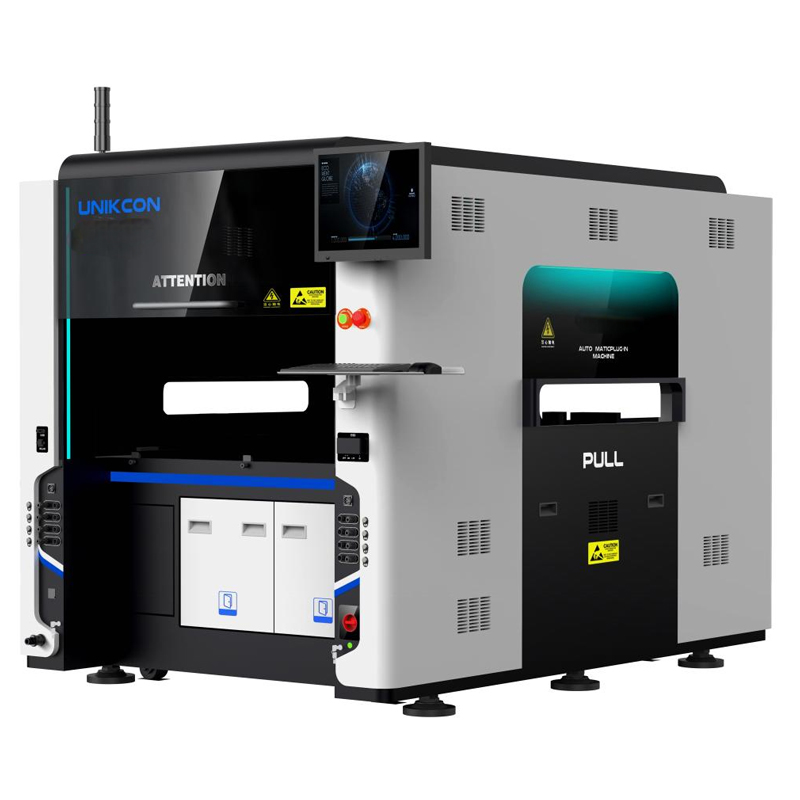

12 heads odd-shaped DIP automatic insertion machines EM2-12S

Product features

1.Fast plug-in speed, multiple placements of feeders, and high stability

2.Substrate mechanical positioning + visual positioning Mark point, high precision

3.Fast line change, various types of corresponding materials

4.Strong versatility, independent Feeder, easy to replace

5.Automatic feeding of components in bulk, tape, tube and tray

keywords: tht insertion machine, tht insert machine, odd-shaped insertion machine, odd-shaped insert machine, odd-formed machine, odd-formed insertion machine, odd-form insertion machine, odd-shaped tht machine, dip machine, dip insertion machine, dip insert machine, through hole technology insert machine

EM2-12S series technology data sheet | ||||||||

machine dimension (include keyboard and signal light) | 1550×2000×1550mm (LxWxH) | PCB height(up/down) | 70mm/40mm(optional can be customized to 80mm) | |||||

weight | 2200kg | PCB max weight (include component, jigs) | ≤10Kg(chain) ≤3kg (belt) | |||||

OS | Windows | door quantity | 2 | |||||

PCB edge width/board thickness (include jig) | 0.5-2mm/0.5-20mm | PCB fixed method | Servo up support/ Cylinder clamping | |||||

door safe sensor detection | standard | rail | chain | |||||

air source | 0.45-0.65MPa, 300 liter/min,the compressed air is dried and filtered | PCB transport direction | L→R/R→L | |||||

max power | 220V ±10% ,50Hz,3.5KW | Guide | 3 phases to transport | |||||

normal working power | 2.5KW | guide width adjust | Auto | |||||

number of insertion axis | 12 | transport heigh | 900±20mm | |||||

max component size | 3.0*3.0mm-35*35mm(L*W) diagonal≤50mm | insert clinch module | optional | |||||

Up side | Bottom side | 0.5mm-55mm | ≤40mm | signal interface | standard | |||

picking method | Nozzle/ Grippers | MES | open data software port can be used for data docking with the MES system | |||||

fastest inserting speed | 0.6-0.8s | Imaging system | Mark CCD(Top) | 2 | ||||

insert accuracy(3ó) | CPK≥1.0 | ≤±0.025mm @ 3 sigma/CPK≥1.33) | Component CCD (Bottom) | 6 | ||||

Insert force | 50N(adjustable) | max number of feeder (double side) | Radial tape feeder | 16 pcs | ||||

insertion direction | 0-360° | Axial tape feeder | 12-16 pcs | |||||

component weight | ≤300g | tube feeder | 16 pcs | |||||

guide max size (dual lane) | 50*50-360*300mm | linear feeder | 90mm/16pcs,140mm/12pcs | |||||

guide max size (single lane) | 50*50-360*610mm(1st time fixed pcb) 50*50-720*610mm(2nd time fixed pcb) | bowl feeder | 4pcs | |||||

Yield | ≥99.5% | tray feeder | 4pcs | |||||

feeder station number (double side feeding) | 8-16 pcs | |||||||

contact me freely if you are interested!

+86 15811817234